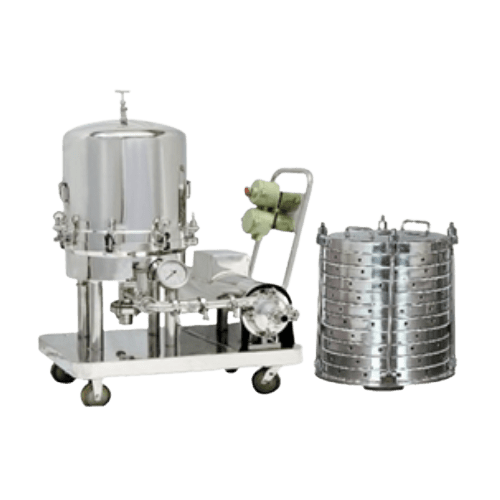

From Pharmachem Cosmetics Industries, the Agitated Filter provided by Agitated Nutsche Filter Dryer Manufacturers in Mumbai is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed operation confirms odorless, contaminated, and non-polluting working conditions keeping product purity and hygiene. Because of all these qualities we are leading as the best filter dryer. From Pharmachem Cosmetics Industries, the Agitated Filter provided by Agitated Nutsche Filter Dryer Manufacturers in Mumbai is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed operation confirms odorless, contaminated, and non-polluting working conditions keeping product purity and hygiene. Because of all these qualities we are leading as the best filter dryer.

Agitated Nutsche Filter Dryer Suppliers in Mumbai, supplies the progressive technology of agitation and hydraulics used in the equipment making it adaptable and user-friendly. The resulting wet cake can be resurged and eroded carefully with water or solvents unlike in” NUTSCHE” type filters or centrifuges. Wash liquid quantity can be organized and cast off, reducing effluent load. The discharge of wet cake is instinctive.

We are a leading Agitated Nutsche Filter Dryer Manufacturers and Suppliers in India. If the process demands filtration in chilled or hot conditions, it is also possible. Drying of wet cake is also possible when drying structures are incorporated. All these attributes contribute to its distinction as the premier exporter, particularly recognized. All of the above parameters make it the best and most prominent leader in the offering Category we are a prominent and top-most choice of individuals with prioritize delivering advanced solutions.

Salient Features:-

- Aimed and Manufactured to suit critical hygienic conditions of the pharma and food industries. (cGMP MODEL)

- The detachable bottom is activated by hydraulic cylinders and held tightly with zero leakage.

- Offered in various ingredients of constructions, like stainless steel, carbon steel, rubber-lined carbon steel, and lead-lined carbon steel.

- Offered in a varied range of filtration area capacities.

- The significant squeezing of the filter cake is possible, thereby resulting in much lower residual moisture in the cake, resulting in a discount in energy requirement for drying of filter cake by up to 40% depending on cake features.

- The process of operation is bound, neat, and hygienic. These conditions are admirable for solvent recovery, and handling of toxic and hazardous materials without human intervention.

- Allows easy, non-manual, and automatic cake/solid discharge. A scraper blade is delivered to scrap the material which may stay on the shell.

- The unit is designed with minimum repair features.

- Hollow shaft and Hollow Blade for full drying.

- Especially intended tank cleaning nozzle is provided for thorough cleaning of the inside of the filter body.

Technical Specifications

| Model |

ANFD-50 |

ANFD-100 |

ANFD-200 |

ANFD-300 |

ANFD-500 |

ANFD-1000 |

ANFD-1500 |

ANFD-2000 |

ANFD-3000 |

ANFD-5000 |

| WORKING VOLUME |

50 |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

| CAKE VOLUME |

25 |

50 |

100 |

150 |

200 |

400 |

750 |

1000 |

1500 |

2500 |

| FILTER AREA |

0.2 |

0.4 |

0.5 |

0.6 |

0.75 |

1.1 |

1.5 |

2.0 |

3.0 |

5.0 |

| VESSEL DIA |

425 |

600 |

700 |

800 |

1000 |

1200 |

1400 |

1600 |

2000 |

2500 |

| VESSEL HT |

400 |

400 |

550 |

600 |

600 |

900 |

1000 |

1000 |

1000 |

1000 |

| BOTTOM OPENING STROKE |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

| DISCHARGE VALVE ID |

150 |

150 |

200 |

200 |

250 |

300 |

300 |

400 |

450 |

450 |

| AGITATOR RPM |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

| AGITATOR DRIVE |

1 |

1 |

2 |

3 |

5 |

7.5 |

10 |

12.5 |

15 |

20 |

| AGITATOR VERTICAL STROKE |

200 |

200 |

200 |

200 |

250 |

250 |

300 |

400 |

450 |

450 |

| AGITATOR UP DOWN SPEED |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

| OVERALL DIMENSION |

1300×1300×2400 |

1500×1500×2500 |

1700×1700×3000 |

1800×1800×3000 |

2000×2000×3300 |

2200×2500×3675 |

2300×2500×3800 |

2500×2500×3800 |

2800×2800×4375 |

3500×3500×4600 |

|