| Liquid Injection |

| Pharmaceuticals :: Injectable Section :: Liquid Injection |

|

| Sterile Mixing Vessel |

|

Sterile Mixing Vessel is the most used magnetic mixing for liquid injectibles.

- It consists of impeller, bearing, weld plate, drive unit & Control box. Generally two impeller designs are available

- Aseptic Design: It is ideal for critical applications. It has horizontal flow channels which uses the differential pressure created during rotation, ensures continuously purging of liquid through the bearing & from beneath the impeller. This feature optimises the cleaning & steam sterillization of the impeller assemble.

- Open Design: It is used for less critical applications as as cost effective alternative: both impeller types use the same bearing & weld plate assemble & are fully interchangeable.

- It is the natural choice for application where shear forces are not critical.

- It shows excellent CIP performance & can be cleaned efficiently using typical in-vessel equipment, purging directly to drain.

Salient Features:

- PLC Panel.

- Load Cell for auto weighing.

- Magnetic Stirrer. ( Roplan/Mariotti & Pecini Make )

Capacities Available:

100 ltrs. to 1000 ltrs. |

|

| Sterile Pressure Vessel |

Salient Features Salient Features

- Zerohold up aseptic design of bottom outlet valve

- Calibratedfull view glass for the blending vessel

- CIPand SIP style design of vessel, fittings and piping

- Injectionports, injection needles available on the top of the lid

- Volumemonitoring by load cells

- Process Automation

APPLICATIONS:

Pharmaceuticals

- SterileSolutions

- Vial

- Ampoules

- I.V. Fluids

- Aerosols

- LVP& SVP Solutions

Biopharmaceuticals

- Vaccines

- HumanInsulin

- Serums

- PlasmaFractions

- Bacteriaand cell cultures

|

| |

|

| Sterile Filling Vessel |

It is made as per WHO & US FDA standards to manufacture sterile solutions. This is a completely closed vessel with agitator mounted on top dome. It is made as per WHO & US FDA standards to manufacture sterile solutions. This is a completely closed vessel with agitator mounted on top dome.

The vessel will be available with different accessories for different applications i.e. standard stirrer/magnetic stirrer/ as required by the customers.

Salient Features :

- Design as per ASME code.

- No stagnant point, internal surfaces are 0.28 Ra finish.

- All contact parts /surfaces made out of SS 316 / SS 316L quality.

- Electro polished from inside.

- The vessel will be jacketed, insulated and cladded by SS 304 sheet.

- Spray ball for CIP /SIP system.

- Flush bottom valve.

- Vary speed drive.

- Steam/Electrical heating.

If required, Load cell/capacitance type level indicator will be provided to measure the volume inside the tank.

|

| |

|

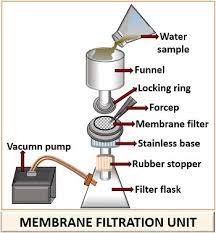

| Memberane Filter |

Membrane Filter is made of AISI SS 316 & used for filteration of sterile liquids. Membrane Filter is made of AISI SS 316 & used for filteration of sterile liquids.

- The unit is provided with two silicon gaskets and support screen with non-sticking mirror finish with bolts and ring nuts.

- An air escape valve is also fitted to remove inside air.

Sizes Available :

|

|

| Dry Sterilizer |

- Decontaminate, clean, and dry all instruments and other items to be sterilized.

- Wrap the instruments and other items using foil, double-layered cotton, or muslin fabric; put unwrapped instruments and other items on a tray or shelf; or place instruments and other items in a metal, lidded container.

- Because dry-heat sterilization works by raising the temperature of the entire item to the designated temperature, it is not necessary to open or unlock hinged instruments or other items or to disassemble those with sliding or multiple parts. In addition, instruments and other items can be placed in closed containers.

- Place instruments and other items in the oven, and heat to the designated temperature. The oven must have a thermometer or temperature gauge to make sure the designated temperature is reached.

- Use the list here to determine the appropriate amount of time to sterilize instruments and other items for different temperatures.

- Do not begin timing until the oven reaches the desired temperature, and do not open the oven door or add or remove any items.

- The times shown here represent the amount of time that items must be kept at the desired temperature to ensure that sterilization is achieved. Keep in mind that the total cycle time--including heating the oven to the correct temperature, sterilization, and cooling--is usually twice as long as the time noted here.

- Because dry heat can dull sharp instruments and needles, these items should not be sterilized at temperatures higher than 160 degrees C.

- Leave items in the oven to cool before removing. When they are cool, remove items using sterile pickups and use or store immediately.

- Store items properly. Proper storage is as important as the sterilization process itself:

- Wrapped items. Under optimal storage conditions and with minimal handling, properly wrapped items can be considered sterile as long as they remain intact and dry. For optimal storage, place sterile packs in closed cabinets in areas that are not heavily trafficked, have moderate temperature, and are dry or of low humidity. When in doubt about the sterility of a pack, consider it contaminated and desterilize it.

- Unwrapped items. Use unwrapped items immediately after removal from the autoclave or keep them in a covered, sterile container for up to one week.

|

| |

|

| Auto Clave |

Robust construction of chamber.

Robust construction of chamber.- Model is available from 1/2 CU.MTR TO 20 CU.MTR.

- Easy to operate.

- Fully automatic operation based on PLC control (optional).

- Semi Automatic (Pneumatically Operated Ball Valave) Control

- Contact parts are SS 304 / 316.

- IQ/OQ/DQ documentation(OPTIONAL).

- It is useful for prevention of micro biological contamination retairing flavour useful for treatment of spices, dried nuts, Foods Packed cereals etc.

Some of the salient features of our sterilizers are as follows:

- Self locking safety door-cannot be opened while chamber is under pressure.

- Gauge glass with automatic closing safety valve.

- Heat resistant silicone door gasket

- Pressure switch (on electric models) economic power consumption

- Low water protection system, to protect the electric heaters

- Temperature Gauge: Digital temp. indicators/controllers (optional)

- Vacuum breakers, dryer

- Safety value for the jacket and boiler

- Hydraulically test to 2.5 times the designed working pressure.

|

| |

|

| Vessel With magnetic Stirrer |

he stainless steel top housing series of Magnetic Stirrers are most compact models. PMDC motor gives high torque even at lower speeds and maintains speed stability despite viscosity or volume changes. Accurate steeples speed control allows smooth variation up to 1200 rpm. Stirring is accomplished by a small Teflon coated magnetic paddle to be placed in the container. he stainless steel top housing series of Magnetic Stirrers are most compact models. PMDC motor gives high torque even at lower speeds and maintains speed stability despite viscosity or volume changes. Accurate steeples speed control allows smooth variation up to 1200 rpm. Stirring is accomplished by a small Teflon coated magnetic paddle to be placed in the container.

Technical Data :

| MS 500 |

500 ml |

- |

105 x 135 x 70 |

Q-18A |

7 x 15 mm |

| 1 ML |

1 |

- |

145 x 185 x 135 |

Q-19 |

9 x 25 mm |

| 2 ML |

2 |

- |

145 x 185 x 135 |

Q-19A |

9 x 35 mm |

| 5 ML |

5 |

- |

180 x 195 x 135 |

Q-20A |

13 x 50 mm |

|

| |

|

| Multi Colimn Distillation Plant |

Multi column distillation plant is based on FINN AQUA design and it produces pyrogen free sterile water (W. F. I.) which meets the requirement of Indian, British & United States Pharmacopoeia. Multi column distillation plant is based on FINN AQUA design and it produces pyrogen free sterile water (W. F. I.) which meets the requirement of Indian, British & United States Pharmacopoeia.

It is available from 50 ltrs/hr (Lab Model) to 3000 ltrs/hr. The WFI produced by these plants is quite economical due to low maintenance and low operational cost.

Special Features :

- All contact parts are of SS 316 / SS 316 L quality and are electropolished.

- All fittings, sanitary triclover type.

- Double safety provided in the first column as boiler steam is present there.

- PLC based fully automatic panel board provided with printer.

- The design is compact & economical.

- 5 years guarantee for columns and free replacement will be given if columns will be found cracked.

|

| |

|

| Bottle Washing Machine |

| Technical Specification: |

| Wash Cycle |

First Wash : 4000Ltrs/Hour Approx at 15PSI.(Detergeant Water). First Wash : 4000Ltrs/Hour Approx at 15PSI.(Detergeant Water).

Second Wash : Minimum Consumption as such, water loss during

recirculation shalL be ompensated. (Steem/Hot Water).

Third Wash : 700 Ltrs/Hour Approx at 15 PSI. (D.M. or DL. Water).

Fourth Wash : 15 PSI (Air)

Outside wash : 1200 Ltrs/Hour Approx at 15 PSI (Ordinary Water). |

| Electrical Motor |

0.5 HP/440 Volts/3 Phase/50Hz (four wire) For Main Machine.

1 HP/440 Volts/3 Phase/50Hz (Four wire) For Water Pump. |

| Ele. Heater |

3 KW. (Four Hot Water) |

| Container Size |

28 mm to 85 mm, Maximum Height 280 mm |

| Container's

Neck Size |

20 mm to 38 mm, Maximum Height 280 mm (With the help of required change parts) |

| Overall Dimension |

1550 mm(L) X 1700 mm (W) X 1350 (H) Approx |

|

| SALIENT FEATURES |

| Geneva Mechanism |

Out side wash system |

| S.S. Elegantly

Matt Finish Body |

70 Ltrs. capacity water tank (Two Nos.) |

|

|

| Centrifugal Pump |

Centrifugal monoblock pumps in sanitary design are available in various sizes and capacities. Pumps can be used for transfer of liquids, semi solids etc. All pumps are in S.S. 316 contact parts and are available from 0.5 HP to 20 Hp capacities. Inlet & Outlet can be given in Triclover or Din fittings as per clients requirements. Centrifugal monoblock pumps in sanitary design are available in various sizes and capacities. Pumps can be used for transfer of liquids, semi solids etc. All pumps are in S.S. 316 contact parts and are available from 0.5 HP to 20 Hp capacities. Inlet & Outlet can be given in Triclover or Din fittings as per clients requirements. |