THE FACILITY CONSISTS OF : THE FACILITY CONSISTS OF :

- Sugar Syrup Vessel

- Online sugar syrup prefilter

- Manufacturing Vessel

- Storage Vessel

- Vacuum system for transfer of sugar syrup

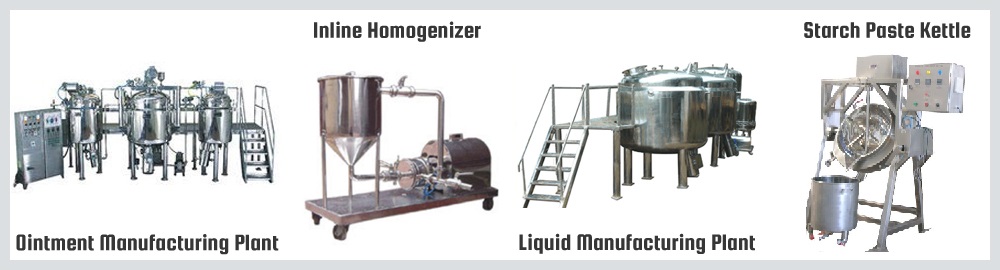

- Filter press / Inline Homogeniser

- Product piping

- Control panels

UNIQUE FEATURES OF THE FACILITY : UNIQUE FEATURES OF THE FACILITY :

- The liquid oral manufacturing plant is designed to be operated by one operator and one helper, saving on precious man-power costs.

- Sugar syrup and manufacturing vessels are provided with limpet coils for heating and cooling, designed for internal vacuum to facilitate transfer of sugar directly from stores to sugar syrup vessel.

- Sugar syrup is transferred to manufacturing vessel through online sugar syrup prefilter by vacuum.

- Entry of all propeller agitators are from bottom through a specially designed cartridge mechanical seal with TC/TC seal face.

- The advantage of the bottom propeller agitator over the conventional agitator is that there are no vibrations of shaft, no couplings in the drive assembly, leading to lower maintenance cost for liquid oral manufacturing plant.

Pipes, pipe fittings and valves are of SS 316, seamless, internally electropolished with DIN standard unions and silicon Gaskets. Pipes, pipe fittings and valves are of SS 316, seamless, internally electropolished with DIN standard unions and silicon Gaskets. - Manhole of all the vessels are equipped with davit fitting and the cover of the manhole slides instead of being lifted.

PROCESS CONTROL :

Values like current, product temperature are displayed digitally on the electrical control panel.

The mechanical seal is equipped with a water circulating system and has a water detection sensor which trips the motor, if the water circulation to the seal is interrupted.

CAPACITIES AVAILABLE :

500 litres to 15000 litres.

Our Product Keywords

Pharmachem Cosmetic Industries, SYRUP TANK MANUFACTURING IN VASAI, LIQUID SYRUP PLANT MANUFACTURER IN INDIA, LIQUID SYRUP PLANT MANUFACTURERS IN VASAI, LIQUID SYRUP PLANT MANUFACTURERS IN MUMBAI, LIQUID ORAL MANUFACTURING VESSEL IN GUJARAT, SUGAR SYRUP MANUFACTURING PLANT, SUGAR SYRUP MANUFACTURING PLANT FOR PHARMACEUTICAL, SUGAR SYRUP MANUFACTURING PLANT MANUFACTURERS, LIQUID MIXING TANK MANUFACTURERS, SUGAR SYRUP PLANT MANUFACTURERS, WINE MANUFACTURING TANK, SS STORAGE TANK MANUFACTURERS, STAINLESS STEEL STORAGE TANK MANUFACTURERS IN MUMBAI, SS STORAGE TANK MANUFACTURERS IN MUMBAI, SS STORAGE TANK MANUFACTURERS IN MAHARASHTRA, SS STORAGE TANK MANUFACTURERS IN INDIA, STAINLESS STEEL STORAGE TANK MANUFACTURERS, SS STORAGE SILO MANUFACTURERS IN INDIA, SS JACKETED REACTOR MANUFACTURERS, SS REACTION VESSEL MANUFACTURING, LIMPET COIL TANK MANUFACTURERS, PASTE PREPERATION VESSEL MANUFACTURERS IN MUMBAI, LIQUID SYRUP PREPERATION VESSEL MANUFACTURERS IN MAHARASHTRA, AUTOMATIC LIQUID SYRUP PREPERATION VESSEL MANUFACTURERS IN INDIA, LIQUID SYRUP TANK, SS STORAGE TANK, SYRUP ORAL PLANT MANUFACTURERS IN INDIA, LIQUID PLANT MACHINERY MANUFACTURERS, LIQUID PLANT MACHINERY FOR PHARMA, SUGAR SYRUP PLANT, SUGAR SYRUP PLANT MANUFACTURERS, SYRUP PLANT MANUFACTURING MUMBAI, SYRUP PLANT MANUFACTURING INDIA, SUGAR SYRUP PREPARATION PLANT, SUGAR SYRUP PREPARATION VESSEL, SUGAR SYRUP PREPARATION TANK, SUGAR SYRUP PREPARATION KETTLE, SUGAR SYRUP VESSEL, SUGAR MELTING VESSEL, AUTOMATIC SYRUP MANUFACTURING PLANT, MANUFACTURING PREPARATION VESSELS AND HAS CONSOLIDATED A PROCESS SUGAR MELTING VESSEL WITH MIXING STIRRER, SUGAR SYRUP IS PRODUCED IN STEAM OR ELECTRICAL JACKETED HEATER TANK AND THEN SYRUP IS TRANSFERRED TOSUGAR SYRUP HOLDING TANK, SAME IS FILTERED USING PLATE, SYRUP HOLDING VESSEL, SUGAR SYRUP MANUFACTURING PLANT MANUFACTURERS, ORAL LIQUID MANUFACTURING PLANT COMPRISES OF SUGAR SYRUP VESSEL, ONLINE SUGAR SYRUP PRE-FILTER,MANUFACTURING VESSEL STORAGE VESSEL, VACUUM SYSTEM, LIQUUID MANUFACTURING PLANT, MANUFACTURER OF SUGAR SYRUP MAKING MACHINE - SUGAR SYRUP MAKING MACHINE, AUTOMATIC LIQUID/ORAL/SYRUP BOTTLING PLANT -LIQUID/SYRUP/ORAL MANUFACTURING PLANT.

|